From vision to prototype

We see the highest demands as a challenge.

Mario Bolla, Managing Director

Consultation

Demonstration of the technical options and cost saving potential.

- Requirement specification

- Service definition

- Outline of costs

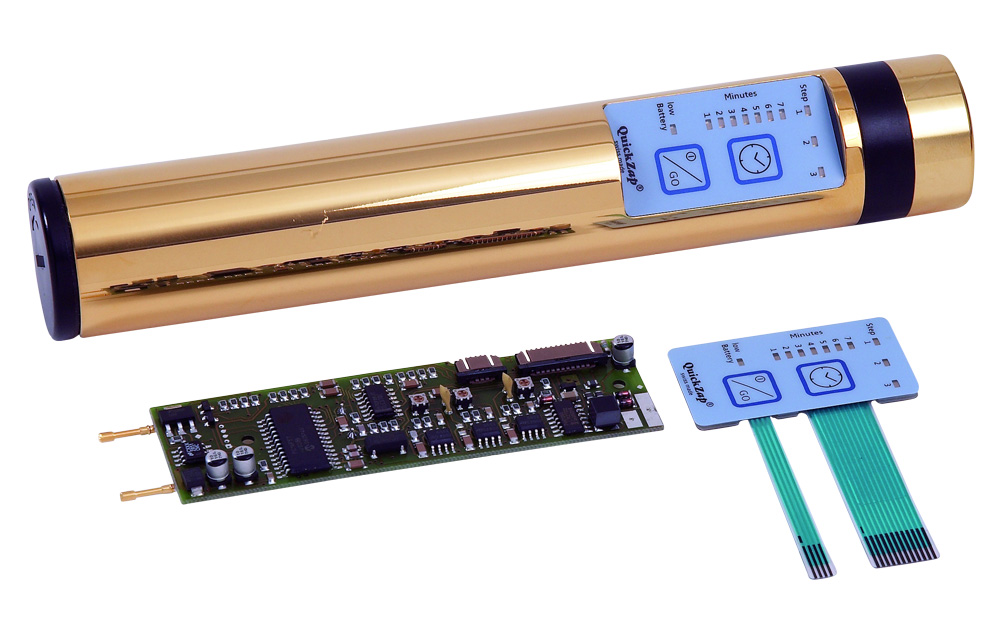

Product Development

- Circuit design

- PCB layout

- Software development

- Prototype

- System test, field test

Product Testing

Extensive know-how and our own EMC test equipment guarantee products that conform to international standards.

Documentation

Clean documentation is an important part of product development.

- Technical data sheet

- Block diagram, technical drawings

- Parts lists

- Description hard and software

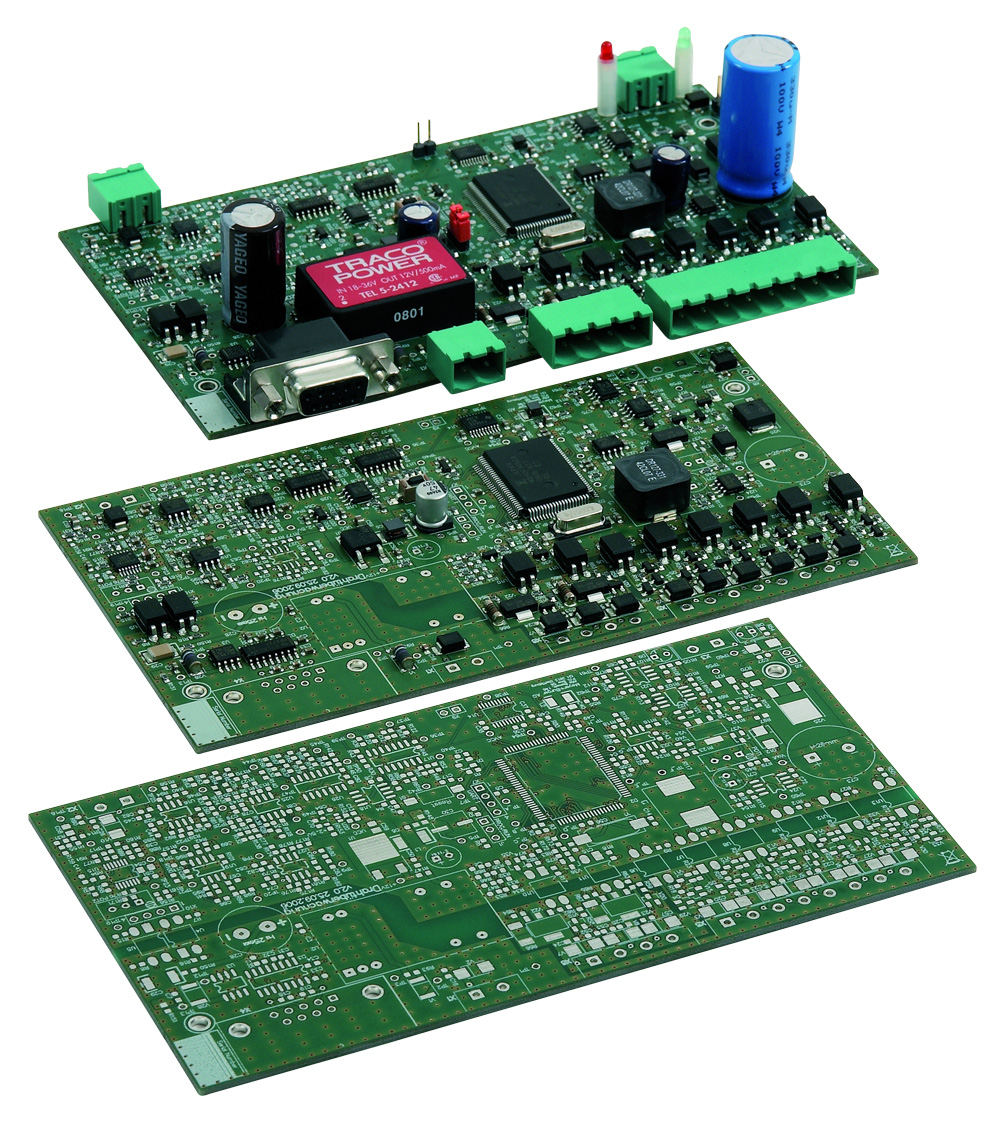

From prototype to series-ready electronics

The simple solutions are often the best

Design Review

Together with the customer, we optimise the series product regarding use, function and costs.

Commercialisation

Comprehensive electronics competence across all processes is the foundation for series-capable products.

- Component approvals

- Creation of CAM dataFertigungsunterlagen

- Production documents

- Production resources and tools

- Sample approval / series approval

Testing system

The right testing concept is crucial for the reliability of the electronics.

- Engineering hardware + software

- Manufacture of test system / test adapter

- Test protocol

Life-Cycle-Management

Life-Cycle-Management zum Schutz der Investition.

Feedback über die gesamte Prozesskette sichert die laufende

Produktoptimierung.

- Redesign: Funktionserweiterungen Hardware + Software

- Reengineering: Komponenten- / Baugruppenersatz

- End-of-Life Management

- Obsolete Management

From procurement to tested product

Series production 100% Swiss made

Work scheduling / PPS

Everything under one roof means short distances and clear communication.

- Data transfer ERP + CAM

- Scheduling

- Initial work

Procurement

Close and long-term partnerships with our suppliers ensure delivery readiness and flexibility.

- EDP-optimised material management

Production

Experience and process reliability result in consistently high production quality. We produce in line with the IPC-A-610 standard.

- THT manual assembly

- SMD automated machine assembly

- Re-flow, vapour phase, wave and selective soldering

- Assembly, wiring

- Automated painting, casting

Testing

Comprehensive product knowledge ensures cost and benefit optimised tests.

- Optical inspection (AOI/MOI), X-ray inspection

- Function test, in-circuit test (ICT)

- Burn-in

Maintenance

Maintenance of product value over the desired service life.

- Repairs

- Software updates

- Repair statistics